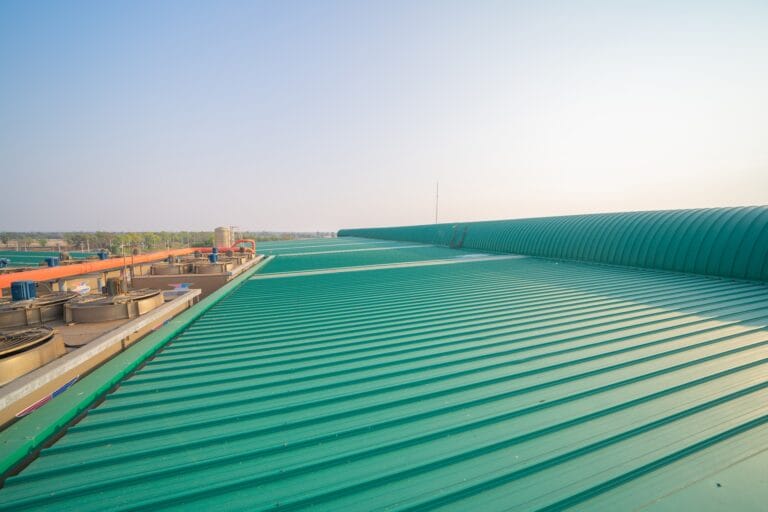

Industrial roofs are essential components for warehouses, factories, and other large buildings. They protect the building and everyone inside from weather conditions and external factors. To ensure these roofs stay effective and safe over time, it’s important to follow specialized guidelines.

Whether you are dealing with metal, flat, or sloped industrial roofs, understanding the unique requirements of each type is crucial. Regular maintenance routines, choosing the right materials, and following proper safety measures can make a significant difference in the lifespan and safety of an industrial roof. In this article, we will share the top 10 industrial roofing tips to help you maintain a safe and long-lasting roof.

Understand Your Industrial Roof’s Unique Requirements

Different industrial roofs have specific needs that influence how they should be maintained and repaired. Understanding the type of roof you have helps in tailoring the best practices for its upkeep.

- Flat Roofs: Often seen on warehouses and commercial buildings, flat roofs are simple in design but require careful maintenance to avoid water pooling. Regular checks for drainage systems and waterproof membranes are crucial.

- Metal Roofs: Metal roofs are popular for industrial buildings due to their longevity and durability. They are resistant to extreme weather but need inspections for rust and seal integrity to ensure they remain leak-free.

- Sloped Roofs: These roofs are designed to facilitate water runoff but are more complex to maintain due to their angle. Regular inspections for shingle integrity and structural support help in preventing long-term damage.

Each type of roof material and design impacts how you approach its maintenance. Understanding these requirements allows you to implement specific care strategies that ensure the roof’s longevity and functionality.

Regular Maintenance Is Key

Regular maintenance of industrial roofs cannot be overstated. It is vital for preventing small issues from becoming major problems. Regular inspections play a significant role in this process.

- Bi-Annual Inspections: You should conduct inspections at least twice a year, ideally in the spring and fall. Look for issues like cracks, leaks, or signs of wear and tear.

- Post-Storm Checks: After severe weather events, check the roof immediately for damage. Pay attention to any debris, dents, or punctures that may have occurred.

- Gutter and Drain Cleaning: Ensure gutters and drains are clear of debris to prevent water buildup. Clogged systems can lead to leaks and structural damage.

- Professional Assessments: While regular DIY inspections are important, having a professional roofer assess the condition of your roof annually can catch problems you might miss.

Regular maintenance helps in catching potential problems early, saving you from costly repairs down the line. By staying on top of inspections and routine care, you extend the life of your industrial roof and maintain a safe environment for everyone in the building.

Choose the Right Materials

Selecting the right materials for your industrial roof is crucial for its longevity and performance. Each material has distinct advantages and drawbacks, making it essential to choose wisely based on your building’s specific needs.

- Metal Roofing: Metal roofs are incredibly durable, lightweight, and fire-resistant. They can last up to 50 years with proper maintenance. However, they can be noisy during rainstorms and may require additional insulation.

- Ethylene Propylene Diene Terpolymer (EPDM): EPDM roofs, or rubber roofs, offer excellent durability and are resistant to extreme temperatures. They are suitable for flat roofs and can last up to 30 years. One downside is their vulnerability to punctures from sharp objects.

- Thermoplastic Olefin (TPO): TPO roofs are energy efficient and resistant to mold growth. They are also fairly easy to install and can last up to 20-30 years. The main drawback is that low-quality TPO can lead to material failures.

- Built-Up Roofing (BUR): BUR involves multiple layers of bitumen and fabric, creating a highly durable surface perfect for flat roofs. While they provide excellent protection, BUR systems are heavy and require strong structural support.

Understanding the pros and cons of each material helps in making a well-informed decision that balances durability, cost, and performance for your industrial roof.

Implement Safety Measures During Roof Work

Ensuring safety during roof work is pivotal to preventing accidents and injuries. Clear safety guidelines and practices should be followed to protect workers and maintain a secure work environment.

- Proper Training: All workers should receive proper training about safety protocols, equipment usage, and emergency procedures before starting any roofing project.

- Personal Protective Equipment (PPE): Workers must wear appropriate PPE, including hard hats, gloves, non-slip boots, and harnesses. This equipment is essential in minimizing injury risks.

- Use Guardrails and Safety Nets: For areas where falls are a risk, install guardrails, safety nets, or other fall protection systems. These measures are vital for preventing serious injuries or fatalities.

- Ladder Safety: Ensure that ladders are stable and secured before use. Workers should follow proper ascending and descending techniques to avoid slips and falls.

- Weather Conditions: Avoid roofing work during extreme weather conditions such as thunderstorms, high winds, or ice. Working under unsafe weather conditions increases the likelihood of accidents.

- Clear Communication: Use clear signals and communication methods to coordinate movements and tasks on the roof. Good communication helps in reducing misunderstandings and resulting accidents.

Adhering to these safety measures is crucial for maintaining a secure working environment and preventing accidents during roofing tasks.

Conclusion

Maintaining an industrial roof involves understanding its unique requirements, conducting regular maintenance, choosing the right materials, and implementing strict safety measures. By addressing each of these aspects, you can ensure that your industrial roof remains durable, effective, and safe for many years. The right roofing choices not only protect your investment but also contribute to the overall safety and efficiency of your building.

For comprehensive roofing solutions and expert advice, trust AAA Roofing NJ to assist you in maintaining and enhancing the longevity of your industrial roof. Contact our NJ roofing contractor today to learn more about our services and how we can help you with all your roofing needs.